Discussion Forums

Forum Index

> Rifles general discussion

> the 35/303

the 35/303

|

@ 05:42 am (GMT) |

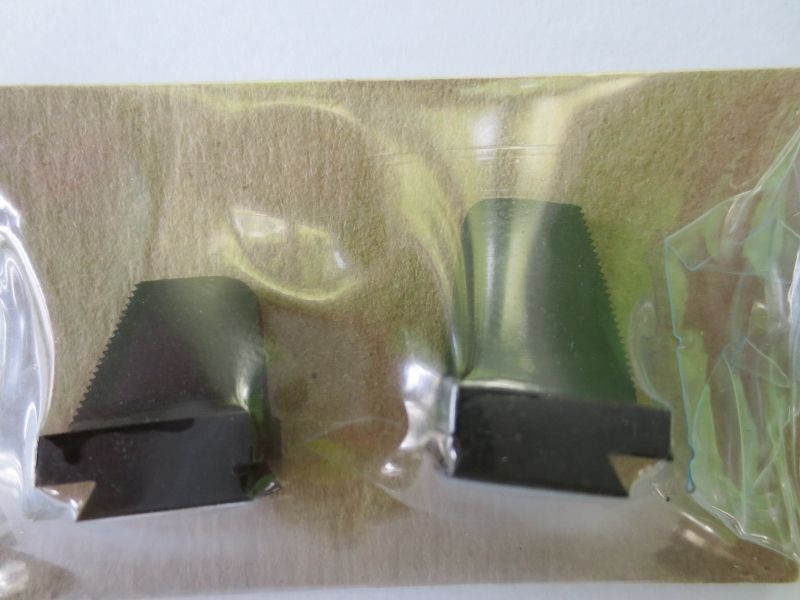

Thomas KitchenHi guys so I finally got a chance to write about the 35/303 project I have been working on.So I better start from the start. When I meet Nathan at reloaders supplies during the year, was when he first mentioned he was trying to convince Grant at trueflite to make a 358 caliber barrel. Fast fordwards few months when I was emailing Nathan about my 308 norma magnum he said if I find the caliber was not to my liking put the rifle a side as he will have a 358 norma magnum reamer as trueflite was going to produce 358 barrels. This is what got the old hampster on the wheels between my ears running about making a 35/303. So it was off to reloaders supplies to get some speer hotcor 358 calber projectiles as they were the cheapest. I started off with a m10 bolt that I tapered to a point to to expand the neck then using a block of wood with a hole in it to seat the projectiles, running them through a lee enfield I found that they would load fine. Having establish that they would work I went on to that dangerous place known as trademe rifle section. I found a nice no4 mk1 sporter, after bit of a bid war and the appropiate paper work I had a rifle in better conditon then I thought for under $100 it even came with the dial up style aparture sights which is handy as I plan to leave this rifle unscoped at this stage. I also needed a more reliable way of necking up the brass thankfully lee precision sell parts straight from there website, I ordered 358 winchester and 35 whelen mandrel and a 358 caliber seating plug. I fitted the 35 whelen mandrel to a 303 full length sizing I had to expand the necks, to seat the projectiles I used the 303 seater die just winding whole die in and out to adjust seating depth at this stage. Now came the next question how the hell was I going to get a barrel chambered in 35/303, after a lot of searching with not much help it was time to contact the guru himself. After a couple emails with Nathan we set up a time for a phone call. We discussed few options like using a 303 reamer then a 358 throat/neck reamer or a sperate throat and neck reamer but it wasn't an ideal situation, we also talked about using a 303 reamer then running a 35 whelen reamer in but this would end up with an improved variant of some sort which may wreck the smooth feeding. Luckily for me one of Nathan has a client that uses lee enfields chambered in 303 epps, so he reached out to him about how smooth the feeding was. Thankfully he got back to Nathan quickly as I wasn't havent much luck with my idea of filling a case with water clamping a bolt in the neck and heating it to expand the case. (bloody plumbers with there far fetched ideas) it was decided that it was best to stick with standard dimensions so not to run into feeding issues and to get a custom reamer made. Nathan also mentioned to me that the 250gr hot cors would be to hard for our local game and that the 225gr gamekings would be a far better options. Trying to find some game kings was proving difficult thankfully the great service at reloaders supplies came through and I had gamekings in my hands in under a week, trying the gamekings I had few feeding issues. Thinking it may be the week spring tension in my magazine I ordered a new repo promag. I was still having issues from one side of the staggered magazine when the bolt is worked slow if it is worked fast it seamed to be fine. Once again I decided to contact Nathan via email, he suggested I might want to try the hornady ftx's designed for the 35 rem as they should perform like the sst's. Back to reloaders supplies I went and thankfully they had some in stock. The ftx feed smoothly straight away, I now had the issue that I had 3 projectiles that I wanted to shoot but needed to make sure that they would all feed smoothly. Noticing that how I was making the dummy was putting the concentricity way off a new method was needed, Nathan had talked about the hornady neck dies in his reloading book. A 338 and 358 hornady neck die was ordered along with a 358 ogive gauge. In the mean time I drilled out the spare 303 seating die I had and put in the 35 seating plug from lee. Once my ordered arrived the fun begun slowly seating projectiles checking it for feeding the checking it with the ogive gauge, after a lot of fine tuning I found and c.o.a.l to the ogive that worked well with all 3 projectiles. I also filed a case neck open so I could check on how much each of the projectile was sitting in the neck. Now came designing a reamer going through saami specs on things like 358win, 35 whelen and 35 rem I notices the 35 rem had a slightly tighter neck then both the 358win and 35 whelen. Nathan had suggested a freebore of .200 thinking that using a slightly tighter neck might help prevent any accuracy issues I measured neck thickness on the ppu brass I was using and did some calculations as the last thing I needed to be doing was neck turning on a bush cartridge, running my calculations pass Nathan he confirmed I shouldn't have any issues. Now came the time for me to design my reamer, having printed off the saami diagrams for 303brit and 35 rem I I needed to combine the two, the mainly problem was since I was leaving the shoulder angles the same as I expanded the neck the neck would become longer as it moved up the shoulder, out came the calculator and some pythagoras. I finally was happy with my calculations so I emailed David Mansons reamers, with my designs explaining the c.o.a.l to the ogive I had worked out plus I wanted .200 freebore. They promptly emailed me back with a design that they had transferred to their drawings. I asked Nathan to just run an eye over it before I confirmed but it seemed to be right and got the nod from Nathan so I confirmed my order. This is the second time I had dealt with the team at David Manson reamers and they really know good customer service which is great to see. While I waited on the reamer I needed to find a replacement front sight as the original one would not be reuseable. After checking a few different options I found skinner sights offer a dovetail front blade that can be filed to the right height that is designed with round edges to minimise hang ups on scrub when bush hunting. I ordered two different heights which arrived from the states without any issues. I now have everything sitting here ready to go im just waiting on the barrels to go into production. The plan is to use a no5 contour sporter grade barrel 22” long with the front sight dovetailed straight into the barrel. its been an interesting experience learning new things and i will be forever greatful that i could contact Nathan when needed, so thank you Nathan and Steph the work you guys do is greatly appreciated. sorry for the marathon read guys but thought i would share the experience. |

Please wait

Please wait